As a key project of the national “eight vertical and eight horizontal” high-speed railway network, Xiong’an-Xinzhou High-speed Railway is accelerating the construction of the entire line. This high-speed railway trunk line that runs through the Taihang Mountains needs to face the complex geological environment in the north – dense fault zones, frequent freeze-thaw cycles, and interlaced karst landforms. The bridge-tunnel ratio of more than 80% makes the construction difficulty increase sharply. Under such harsh conditions, the precision control of the abutment and pier body formwork has become a core link affecting the quality and progress of the project.

Technological breakthroughs behind precision

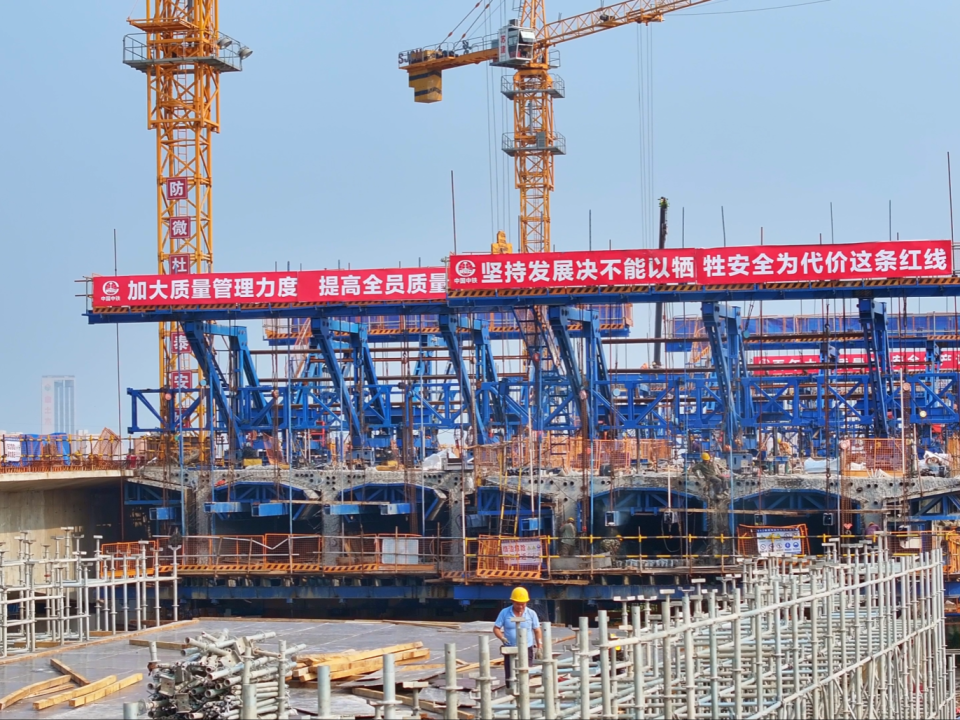

Facing the high-cold and changeable construction environment in the north, traditional formwork is susceptible to temperature fluctuations and geological settlement, resulting in slight deformation of the concrete structure. The reinforced steel formwork system specially developed by Pansol steel formwork greatly improves the structural stability through modular design and precision manufacturing technology. Its innovative hydraulic tensioning system, combined with intelligent temperature control technology, effectively copes with the extreme cold challenge of minus 25℃, and realizes the efficient operation of “dismantling the formwork on the same day and turnover on the next day” in multiple sections.

The construction team reported that after the template system was promoted throughout the Xiongxin High-speed Railway, the apparent quality of key structures was significantly improved, and the defect rate of honeycomb surface and other defects dropped to an extremely low level, laying the foundation for subsequent high-precision construction such as ballastless track.

Dual guarantee of efficiency and quality

Quick disassembly and assembly: pre-assembled template units can be used immediately, shortening the construction period by 30%.

Intelligent adaptation: the adjustable system can flexibly respond to changes in longitudinal slopes of 5‰-40‰, reducing the time spent on on-site adjustments.

Long-lasting and durable: high-strength steel and special anti-corrosion technology ensure that the template can be reused more than 50 times.

In a certain section, the quick disassembly technology of Pansol steel templates solved the problem of concrete maintenance in high-altitude cold areas. Actual measured data showed that after adopting this system, the qualified rate of steel bar protective layer exceeded 97%, and the structural size error was strictly controlled within the specification requirements, becoming the quality benchmark for the entire line.

“Hard-core toolbox” for engineers

“Now steel templates are no longer simple molds, but construction carriers that integrate data and processes.” The on-site technical person in charge said frankly. Pansol steel formwork previews the construction plan through BIM technology, eliminating errors in the virtual modeling stage; its intelligent sensing module can monitor the state of concrete in real time, promoting the transformation of construction from “experience-driven” to “data-driven”. This technological upgrade not only reduces the risk of rework, but also forms a set of replicable complex geological construction plans.

The accelerated advancement of Xiong’an-Xinzhou High-speed Railway has witnessed the transformation of China’s infrastructure from “scale expansion” to “precision revolution”. Pansol steel formwork responds to the “geological test paper” of northern construction with technological innovation, which not only presses the “fast forward button” for high-speed rail construction, but also sets a model for quality control in complex environments for the industry. When the long steel dragon passes through the mountains in the future, these “invisible heroes” buried deep underground will continue to tell the story of precision made in China.